c2439c95400dae48c68eaf44f529f1fd2c652059

NixiESP12

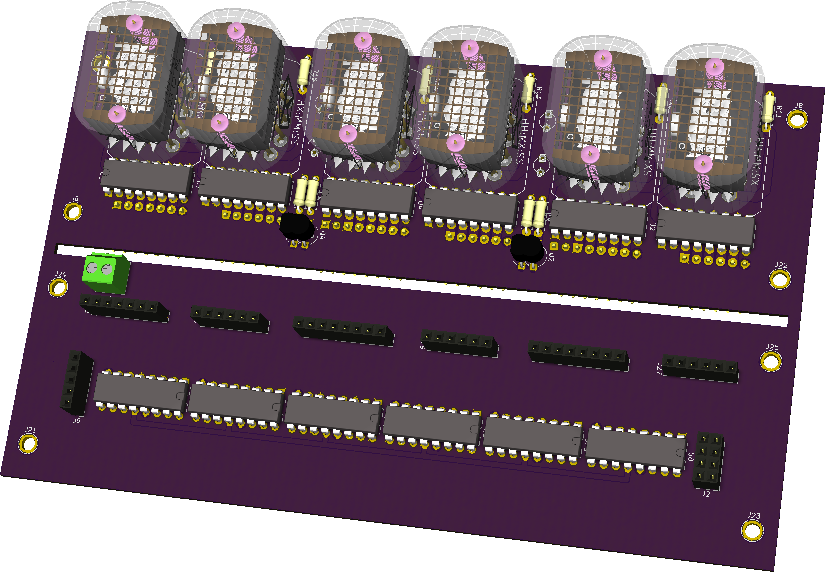

Intro

Yet another Nixie clock project!

Some highlights:

- K155ID1 driven IN-12A or IN-12B tubes for hour, minute, seconds

- BS107 driven IN-6 or similar neon bulbs for digit separation

- 74HC595 for serial to parallel conversion

- ESP8266 for time synchronization

- LM1117-3.3V and LM1117-5V regulators for logic power supply

- No tube step up converter on-board, pin headers for connecting third party power supply

- KiCad design with 3D models from http://miniwatt.info

Some KiCad screenshots:

Install

Boot ESP8266 with program pin held low and flash MicroPython:

cd firmware

make erase

make flash

Reboot ESP8266 and finish with by uploading scripts:

make upload

Power cycle the device and via WiFi connect to the device,

network name is MicroPython-XXXXXX and password is micropythoN.

Navigate to http://192.168.4.1 to start the configuration wizard.

## Assembly tips

Some cheap 1117V regulators don't offer short circuit protection

and once blown pass through input voltage,

make sure you get ones with protection otherwise you can fry ESP8266

or serial-to-parallel chips.

Once the PCB is milled or etched make sure you clean the 180V rails thoroughly,

that voltage is high enough to cross gaps of 0.1mm.

Once that happens it burns a thick dark trace into the fiberglass of PCB and

it's pretty tricky to clean up.

The PCB is designed with 0.4mm clearance to be compliant with HV designs.

This clearance of course assumes that PCB traces are covered.

Either use solder mask or conformal coating.

Use the bench power supply to gradually power up the device,

at 9V set current limiter to 0.5A max.

5V linear regulator can be omitted and bypassed if 5V wall adapter is always used.

Otherwise 6V-12V wall adapters are suitable,

Thincan DBE60 9V wall adapters are pretty much perfect for the job.

Note that the higher the input voltage the more power is dissipated

as heat on the 3.3V and 5V voltage regulators, thus at 12V the device gets really hot.

Description

Languages

C++

73.5%

Python

18.4%

Makefile

6%

OpenSCAD

2.1%